WARWICK workholding Simple, Cheap and Reliable

SIMPLE-KSZ Just to save time

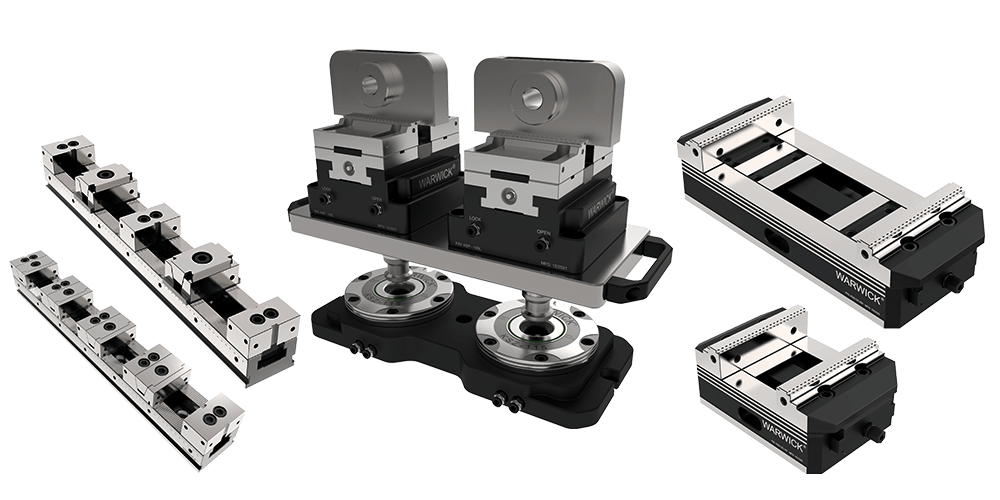

SIMPLE-KSZ is the modular quick-change pallet system for very fast and extremely precise resetting of workpieces, clamping devices or other equipment on modern 3-, 4- or 5-axis machining centers. It reduces the retooling times up to 90% and thus provides optimal utilization of the machine capacity.

WARWICK uses a modular system with countless combinations of standard clamping devices for different types of machines

All modules can be operated at a system pressure of 6.5 bar without the need for an additional booster and are positioned by taper with a repeatability of < 0.005 mm

The patented drive system achieves maximum pull-down force, and the pull-down force of different models is 6.5-21KN.

These include an increased pull-down function and self-locking, which remains available when the air is cut off, to maximize the performance of the CNC machine.

Each KSZ module uses a common clamping pin size to ensure 100% compatibility without the risk of mix-ups or operator errors

Airflow is ejected from the center to protect the replacement interface from coolant, dust, and debris

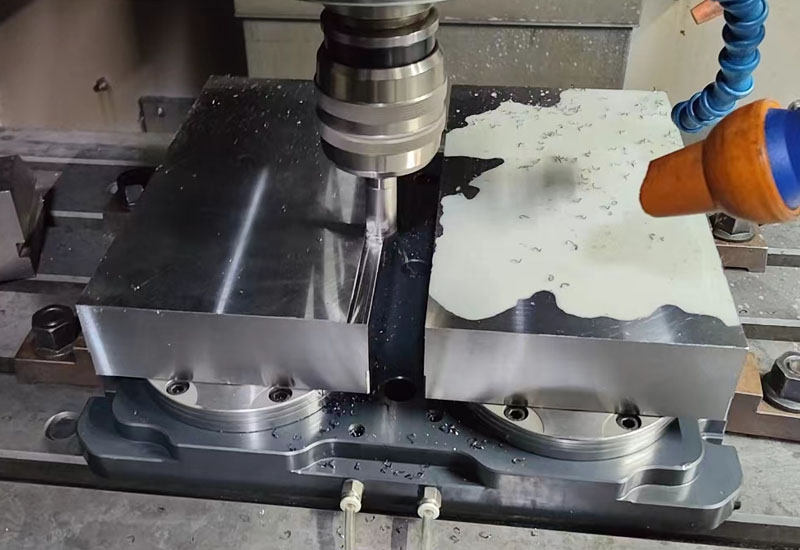

Use examples

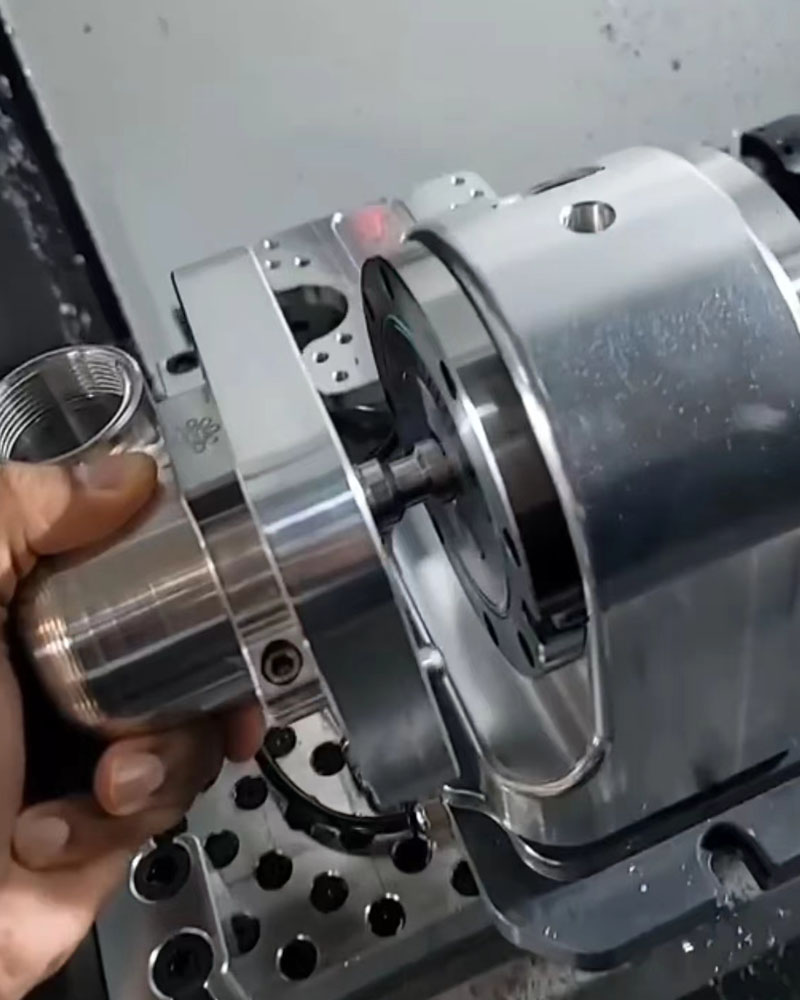

SIMPLE-KSZ

Clamping, in common sense, is very difficult to achieve complete positioning; The X, Y, Z, A, B, and C axes need to be defined at the same time. Technology is used to solve these very difficult things, just like in the picture.

His operation is very simple, he only needs to turn on the compressed air, take down the processed workpiece, put on a workpiece that has not been processed, turn off the compressed air, and then the clamping is completed.

The locking and positioning of the workpiece does not require the operator to ensure it, and the use of the KSZ positioning system can greatly reduce the time required for clamping.