WARWICK Workholding- Simple,Affordable and Reliable

Simple series

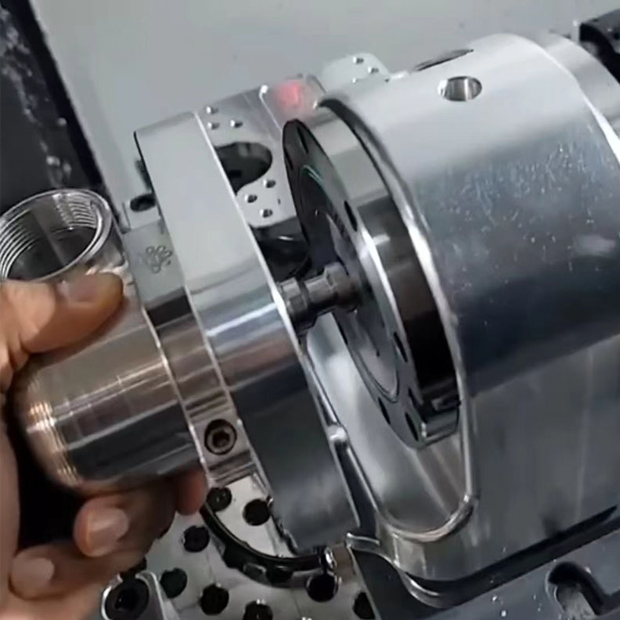

KSZ Zero-point positioning system

The KSZ is a modular quick-change pallet system for quickly and precisely resetting workpieces and clamping machines on 3-, 4- or 5-axis machining centers. It reduces recalibration time by up to 90%, providing optimal machine utilization.

Precision

Fast

Stable

Reliable series

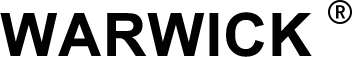

KSP Pneumatic self-centering vise

KSP Pneumatic Self-Centering Vise – Reliable vise.

It is a vise that uses pneumatic and spring actuation for centering clamping,

It has the characteristics of extremely high repeatable clamping accuracy and fast clamping speed.

Extremely high repeatability of clamping

Fast clamping

Suitable for automatic clamping

Affordable series

KSS self-centering vise

The preloaded and backlash-free center bearing guarantees repeatability, roughing and finishing of the parts with just one clamping system.

Integrated chip evacuation and screw protection for increased vise reliability.

The center clamping vise is also ideal for parts storage machining solutions.

The KSS self-centering vise has a KSZ interface that provides a range of versatile combination functions with Warwick’s heavy-duty KSZ115 modular system.

Screw protection

Cutting drainage

One module completes roughing and finishing

Affordable series

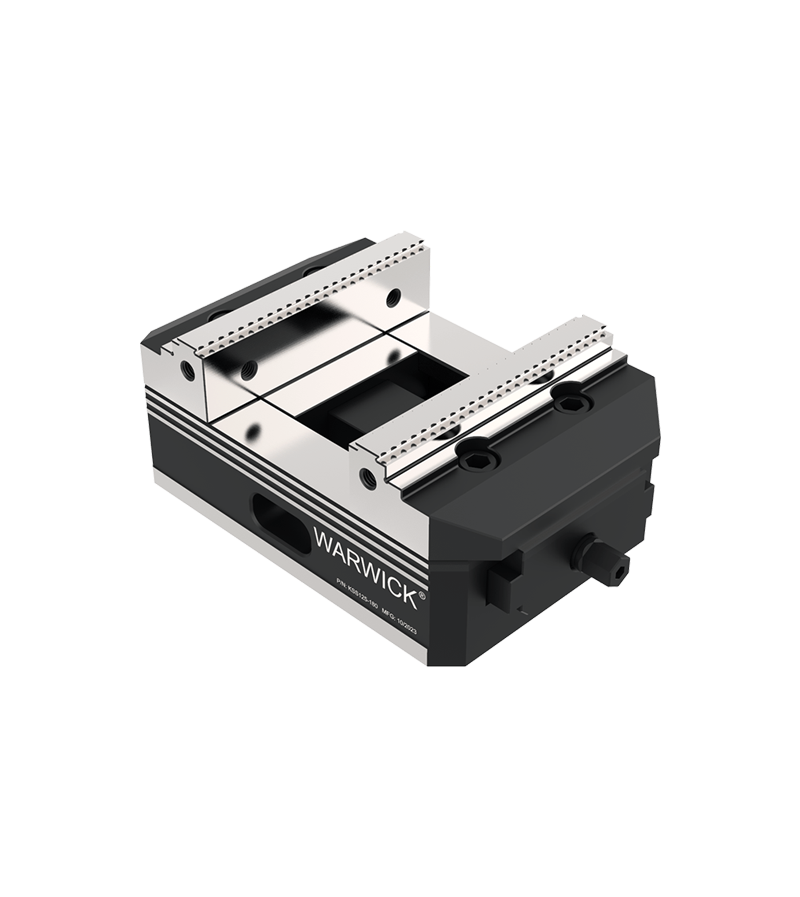

KSD multi-station vise

Modular, multi-clamping system.

Due to the thinner jaws, these parts are now more compact, which results in a larger clamping range.

Thanks to the KSZ interface, the KSD clamping guide can be combined with WARWICK’s KSZ90 or KSZ115 modular systems to provide a range of versatile combination options.

Modularization

Multi-piece clamping

Multiple vises are used in parallel

Advantages of WARWICK Workholding Devices

Advantages of the zero point positioning system

The zero point positioning system is a unique positioning and locking device that allows the workpiece to be quickly switched between different machines.

■ Repeat positioning accuracy≤0.005mm

■ Maximum locking tension 24000N

■ Reduce set-up time, improve part accuracy, and shorten clamping time

■ Save up to 90% of time and increase productivity by up to 70% in the manufacturing process.

Pneumatic self-centering vise

Compressed air drive, which automatically finds the center of the workpiece, can be used in automation scenarios.

■ Automatic clamping, 100 times repeatable positioning accuracy≤0.02mm

■ The clamping cycle is controlled by compressed air

■ Clamping force up to 24 KN

■ It can be applied to robot and automation scenarios